Unveiling an Extensive Choice of Resilient Undercarriage Parts for Heavy Machinery

Wiki Article

Discover Undercarriage Components for Heavy Machinery

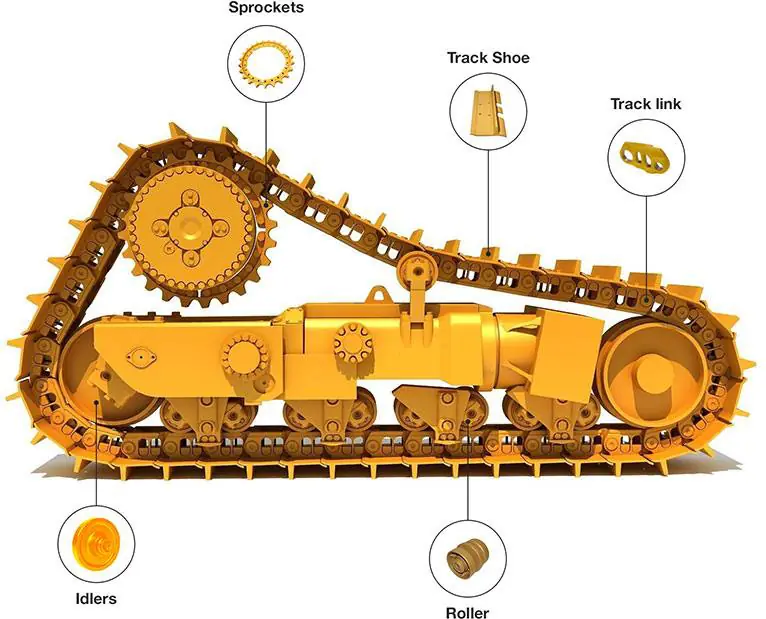

Recognizing the ins and outs of undercarriage parts is necessary for the optimum performance and longevity of heavy machinery. From track footwear to rollers, sprockets, and idlers, each part plays a critical duty in the functionality of the tools.Value of Undercarriage Components

The undercarriage parts of hefty equipment play a crucial function in ensuring the general performance and long life of the equipment. These parts, consisting of tracks, rollers, chains, idlers, and sprockets, form the structure whereupon the equipment runs. A well-kept undercarriage not just offers security and assistance to the hefty machinery but additionally contributes dramatically to its functional performance and performance.

One of the vital advantages of spending in top quality undercarriage components is the decrease of downtime and maintenance prices. By utilizing resilient elements that can hold up against the rigors of durable applications, operators can minimize the requirement for regular repair work and substitutes, hence optimizing the device's uptime and total lifespan.

Additionally, properly functioning undercarriage components guarantee optimal weight maneuverability, distribution, and traction, enabling the hefty equipment to operate smoothly also in difficult terrains. This reliability is crucial for sectors such as mining, agriculture, and construction, where equipment performance straight affects job timelines and earnings. In verdict, the significance of undercarriage components can not be overemphasized in maintaining the efficiency and durability of hefty machinery.

Kinds Of Track Shoes

When taking into consideration the different sorts of track shoes for hefty equipment, it is necessary to review their layout and functionality in connection to specific operational requirements. Track shoes are critical elements of the undercarriage system, offering stability, weight, and grip distribution for heavy equipment such as excavators, excavators, and spider cranes.The most typical kinds of track shoes consist of:

** Grouser Shoes **: Including elevated steel bars (grousers) along the shoe's surface area, these track footwear supply boosted traction in challenging surfaces like mud, snow, and loose crushed rock. undercarriage parts.

** Double Grouser Shoes **: Comparable to grouser footwear but with an extra set of grousers, these track footwear use also higher traction and stability, making them excellent for very rough terrains.

** Triple Grouser Shoes **: With 3 collections of grousers, these track footwear provide optimal traction and stability, making them suitable for the most requiring problems.

Selecting the ideal kind of track footwear is vital for optimizing the performance and durability of heavy machinery while making certain safety and effectiveness throughout operations.

Feature of Rollers and Idlers

this post Rollers and idlers play indispensable duties in supporting and directing the track footwear of hefty machinery throughout operation. By avoiding excessive slack or tightness in the tracks, idlers add to the total stability and efficiency of the machinery.Furthermore, idlers and rollers interact to maintain the track shoes abreast, avoiding them from slipping or hindering off throughout procedure. Properly working idlers and rollers are critical for ensuring the durability of the undercarriage system and optimizing the equipment's performance. Normal upkeep and inspection of these elements are vital to identify any indications of wear or damage at an early stage, protecting against expensive fixings and downtime over time.

Duty of Gears in Machinery

Upkeep Tips for Undercarriage Components

Effective upkeep of undercarriage elements is essential for ensuring the long life and ideal performance of hefty equipment. Regular examination of undercarriage parts such as track chains, rollers, idlers, sprockets, and track shoes is vital to stop unforeseen break downs and costly repair services. One key maintenance suggestion is to More about the author maintain the undercarriage tidy from debris, mud, and various other impurities that can accelerate wear and deterioration. It is likewise essential to make certain proper track tension to prevent early endure components. Greasing the undercarriage parts at recommended intervals helps to minimize rubbing and extend the lifespan of the you can try here components. Keeping track of for any type of uncommon noises, vibrations, or changes in machine efficiency can suggest potential problems with the undercarriage that require instant attention. By complying with these upkeep tips carefully, heavy equipment drivers can decrease downtime, reduce running costs, and optimize the productivity of their devices.Conclusion

Finally, the undercarriage parts of heavy machinery play a critical duty in making sure the smooth performance and durability of the tools. Understanding the significance of track shoes, idlers, gears, and rollers, as well as carrying out appropriate upkeep practices, can significantly influence the overall performance and effectiveness of the machinery (undercarriage parts). Normal examination and prompt substitute of damaged parts are crucial in making best use of the life expectancy and productivity of hefty machineryRollers and idlers play essential duties in sustaining and assisting the track shoes of heavy machinery throughout procedure.In heavy equipment, sprockets offer a crucial function in transferring power from the engine to the tracks, allowing the devices to relocate effectively and successfully. These elements are linked to the axles or final drives of the equipment and job in combination with the tracks to propel the tools onward or backward. Routine inspection of undercarriage parts such as track chains, rollers, idlers, sprockets, and track shoes is critical to prevent unforeseen failures and pricey repair services. Comprehending the relevance of track footwear, sprockets, idlers, and rollers, as well as implementing correct maintenance practices, can greatly affect the overall efficiency and performance of the machinery.

Report this wiki page